Warehouse design: stock rozrakhunkiv. Building throughput and warehouse turnover

Great streams of products to reduce the necessary concentration of viruses. For a whole set of special infrastructure elements, for which there is a supply of electronic enterprises with complete components, and the endowment with ready-made goods. Such a miscellaneous is called warehouses in a wide sense of the word, and in terms of specificity - bases, terminals or skins.

There is a need for warehouse services of wineries from all enterprises, which are engaged in the release of whatever products, trade structures and companies, such as for the provision of services required vitratic materials. Chim is more developed є the structure of the company, it is more important to have a warehouse in the out-of-town state complex.

A special warehouse є to be delivered with a folding object, і from the technical side, і from the management. The need for storage є on all stages of production, from a view of a product to the sale of goods. Therefore, there is a great number of new warehouses, which require classification. The principle of classification, nobility is necessary, the basic principle of robotics warehouses.

Warehouse structure and ownership

Warehouse є not just for households, there are no vantages. In the new one, the internal structure is singular; The warehouse is stored from decilkokh zones, so it can be developed according to the designation and possession can be obtained.

See the following main areas:

- The zone of vantage and vivantage. You can also buy a single or separate distribution on two sides. Near the tsіy zonі there are maidanchiks, which can be in contact with transport without any contact. Vimogi to majdanchikiv are developed in a fallow way by servicing the transport.

- Priymannya zone. There is a given zone to call the addendum from the solution to the attachment. They have a chance to receive vantages and send them right on the spot. As a rule, the zone is highly automated.

- Zberigannya zone. Її loan possession, designated for the acquisition of vantages.

- Sortuvannya zone. I will secure the acceptance of applications for the transport of vantages and transfers from the transport to the vantage zone.

- Expedition zone. Vykonutsya oblik vantazhіv, scho vіdravlyayutsya, store supervised documentation.

- Administrative and gosudarstvo-pobutovі primіshennya.

For the sake of obtaining and transporting vantages, it is necessary to have a versatile possession. In warehouses with small vantages, it is widely possible to stock up on hand attachments, important and overall objects, and move by cranes and navantazhuvachi.

vibir warehouse

Today's markets can be delivered to the smallest, and companies to achieve the highest efficiency of the robot are often required to buy new ones from the warehouse. At the same time, the warehouse will be set up for specific athletes. In order to know the required object, it is necessary to formulate the rules and regulations.

For a number of times when you need more food, vitrata of food will be ineffective. Warehouse area will be paid more, and productivity will be lost on the same. If, before that, the technology of vantage processing will be irrational, then the picture will become better.

From an hour to the choice of a warehouse, followed by keruvatis with clear vimogs until the offensive characteristics:

- The back of the area і ob'єm budіvli;

- Area and visoti zones;

- Number of doors and docks;

- Rozmіri maidanchika for maneuvering transport.

The main staff of є vibir rozmіrіv warehouses For the urahuvannyam of the forecasted change in the flow of vantage ob'єkt, yogo area and obsyag, vikorystovuvalis with the greatest efficiency. Schob assessment of skin technological solution in the warehouse of the state, the introduction of special standards of performance. The number of real indicators recommended to the officers will show that the warehouse will function correctly. Taking into account the established norms to reduce the level of efficiency and effectiveness of the warehouse.

Before the time, like vibrate the warehouse, it went over to the obviousness, it was possible to pretend, the correct formulation, the correctness and the rimming. The best vipadok - if the company is in its own order by the fahivtsy, who may be informed about the news and information, so that it allows them to carry out razrahunki and sruntuvati їkh. Such a robot is highly specialized in the field of singing qualifications, as well as in the most great companies.

Most of the companies do not have such sportsmen in the state, so the optimal entry for them is the participation of companies, so that they can attend special projects on the basis of these projects. The participation of literate people in the future will be less, less, less, as it may be like a pardon with a choice of a warehouse, its planning and equipment.

Classification of warehouses

For a more simple choice, the warehouse should be divided into rіznі vidi in the presence of species signs. You can see the following criteria for choosing a warehouse:

- The assignment to the logistic areas;

- Putting to the first participants in the systems of logic;

- Form of moisture;

- adherence;

- Functional designation;

- Assorted specials;

- Zberigannya mode;

- Technological equipment;

- Type of warehouse buildings;

- Warehouse view;

- Availability of transport links і їх type;

- Scale of activity.

store z great area- from 5 yew. M 2 is often referred to as term_nals.

There are special warehouses, on which comrades are taken, to be imported into the territory of the Russian Federation or to be transported from the country. Zberigannya at cich warehouses is carried out in accordance with the Mitny Code of the Russian Federation. Three warehouses see the warehouses of the hourly collection, there are objects that can be exported, so also imported, from the order to the body of the company to be issued at the vilny obig. Before an hour the goods are collected at the warehouse, they will not be pulled together and paid, and you will not get stuck in the economic policy.

Methods for the classification of warehouse facilities in the Russian Federation

Bagato companies, who can see the information in the logistic and the assessment of the commercial non-destructiveness, the reason for their systems, for which the classification of warehouses is displayed. Tsikavim є the system of the St. Petersburg group of companies "RMS" and the London company Knight Frank, a provincial lighting company in the assessment of all the inconsistencies. A lot of the systems of classification are similar.

The first classification has been broken up in the Russian Federation, so there is a special feature of the central regions of Russia and the main opportunities, in which I respect the rent and purchase in the first place. As far as the classifications are concerned, warehouses are subdivided into 4 categories, which are known by the great Latin letters.

Warehouse class "A"

Warehouse of class A is a modern one-top building, which was carried out with the use of proprietary technologies and high quality materials. Until now, such vimogs are presented:

- The height is not less than 8 m, it is possible to build up the baggage racks;

- Floor with a flat surface, without defects and with anti-friction coatings;

- Possible signalization and automated system for extinguishing sprinkler fire, or powder type;

- Possibility of accurate regulation of temperature conditions;

- Detection of heat dependencies on the gate;

- , Equipped with a hydraulic ramp with height adjustment;

- Central air conditioning;

- Protective signalization and video surveillance of all areas and spaces; ()

- Office services, summaries of the warehouse;

- Necessity of telecoms lines of fiber-optic type;

- Sufficient majdanchik, sob of great valet road trains could easily maneuver and stand in the window;

- Zruchny pid'їzd, relocation of the order with the central highways.

Class B:

- the capital of the top-level booths;

- the height of the stele from 4.5 to 8 m;

- asphalt or concrete podlogs without coverage;

- temperature regime in the range of +10 to +18 ° С;

- Anti-fire system;

- ramp for rozvantazhennya;

- the visibility of the official side;

- telecomunics;

- territory, how to be protected.

Class C:

- capital virobniche for hangar insulation;

- height from 3.5 to 18 m;

- opaluvalne prim_shennya (temperature charge +8: +14 ° С).

- asphalt, slabs or concrete slabs without paving;

- gate to zero point (transport to enter the middle of the area).

Class D:

Such a rank, vimogi to the whole class of warehouses velmi zhorstki. Far from all awakenings are satisfied. Find a lot of food before the warehouses of class D.

- Personal support;

- On'єkti civil defense;

- Neopaluvans and bugs;

- Angari.

Rashta warehousing, in the presence of its constructive features, will be used in class B and C. Klasse will be able to keep the main flow to the third party or rent.

Warehouse Classification

The British company broke up Knight Frank's system, for which visas you can see warehouses and their classification. The system is built on the basis of light-hearted information and is adapted for robots in the Russian Federation. The classification of the given company is accepted by a large number of great companies, which work in the field of assessment of commercial impairments. Infected in the Russian market.

Automated warehouse systems

Rinok grows dynamically warehousing Vimag is from the participants in the classification as well as to the existing ones and will be based on the same criteria. On the Russian market there is a lot of business and living great companies take on the active ways of classifying and awakening. At the end of the day there is a classification of industrial objects, and the distribution of such significant companies, like Knight Frank, can be the basis.

The introduction of a single classification for the business segment of the commercial non-hassle should be put in place of the performance of the operations with the non-hassle objects. V backcountry The basic system is established, on the basis of which classification and designation of warehouses in the logistic statistics. There is an orderly significant range of products, for which warehouses are prickly. The main criterion in the classification is the recognition of the minds that are necessary for the selection of a particular class of products in the warehouse. To that in the designated category, there is a chance to try The main specialty, For example, a refrigeration terminal or a warehouse with a level control.

Warehouse primitives are assigned one of six classes, reproducing from the most recent A + to the lowest D. The scales of the C + and D + classes are not transferred. Increased by 6 classes, it allows more precisely, depending on the level of equipment and efficiency. In general, before the warehouses of the class A + and A, there are more zhorstki vimogas, lower than the analogous class for the classification of the company "RMS".

Warehouse class A +

Naybilsha difference in height: class A + is assigned to buds with a height of 13 m, and class A - 10 m... Also, visibility is spared in the following parameters:

- Crochet columns і appeared between spills;

- Forget the area;

- The availability of the electric power station of the thermal university;

- Number of goods and possessions;

- Availability of the automated system and the distribution of goods, which control the accessibility of the spy;

- Availability of parking for passenger cars;

- Evidence of the garden and cyclone protection;

- Improvement of the territory;

- Vlasna zaliznichna gilka;

- Approvals developer.

For the number of vimogs it is clear that there are a lot of warehouses, which are class A in the classification of the company "RMS", according to the Knight Frank system, class B + or V. There is a large number of significant parameters.

Delivery standard:

- average volume of goods flow V input / output = = 120 m3;

- the coefficient of unequal input to the flow of goods is unequal. input = 1.4;

- Robot interval for unbinding and picking up goods Tvhod = = 4.5 years (from 12.30 to 17.00);

- number of pallets in the back of the vehicle (input) Npall. a / t = 22 pcs.;

- an hour of car rozvantazhennya with urahuvannya technological downtime and an additional hour tresgr = 0.75 h.

The goods arrive at the warehouse in palletized, palletized wagons. Paleti one-born. The goods will be accepted for repeated removal of vehicles. Hour of attracting goods to transport.

Zberigannya standard:

- number of new items that can be stored in warehouses, articles ≤ 100 items;

- average hour of transferring goods to the warehouse Tobor = 15 working days (3 days);

- kofіtsієnt nerіvnomіrnostі zberіgannya goods kneravn. store = 1.4;

- area, yaku borrowed with a pallet, Spall = 1.2 × 0.8 = 0.96 m2;

- the height of the goods on the pallet Npall = 1.2 m.

Every day there is a tendency to increase / decrease in warehouse surplus. Special vimogues to the selection, obrobka, commodity production in the daytime. The parameters of the palette are taken into account for the parameters of the palette.

Vidboru standard: widbir replaces to come in bulk boxes.

Installation standard:

- number of replacement in the body of the car (wyhid) Nzak. a / t = 10 pcs.;

- the efficiency of the outward flow of goods is unequal. vihid = 1.8;

- area, yaku borrowed with a pallet іf zamovlennyam, Szak = 1.2 × 0.8 = 0.96 m2;

- the height of the change on the pallet Nzak = 0.6 m;

- The interval of robots for the renewal of replacement Tvikhod = 3.5 years (from 8.30 to 12.00);

- hour of car lock-up due to technological downtime and extra hour totgr = 0.75 h.

The replacement will be replaced by the freight forwarder for further reconciliation of the route according to the warehouse. An hour of re-routing of routes in accordance with the hour of blocking of vehicles. The goods will be removed from the warehouse in a Gazelle car with a rosip.

For a given butt, the option of mechanized technology for processing commodity flows is clearly visible. Methods of development are presented in the meaning of the earlier statty, that is, the first time it is necessary to continue reading, it is often necessary to become familiar with it again.

VALUE OF ZONES

Visually, the main zones (dilyanki) of operations:

- zone of protection and capture;

- zone of protection and distribution;

- control zone and set;

- transport expedition zone;

- vidvantazhennya zone.

The speedy classification of zones, presented in the front issue of the magazine, is significant for its zagalny character. Our choice of processing zones for the flow of goods will be: a zone of removal and acceptance, a zone of control and assembly, a zone of removal. The zones of distribution (selection) and processing will be the zone of selection and distribution and the zone of transport expedition. Zones with special minds for the collection and processing of commodity flows are not required. The yak is visible from the tribute, the robots from the vantage / attraction of the goods and the robots to early hour... Otzhe, for the economy of the resource and the area of the warehouse, we will additionally set up the summaries of the zone and receive / upgrade. Visually, it is necessary to use the capacity (capacity, area) for the presentation of the operational zones to the warehouse.

ZONE RECEPTION / DEPARTMENT

For the development of the necessary capacity of the zone and for the acquisition / removal of the necessary resources, we need to acquire the warehouse of the first post of acquisition / removal and to calculate the number of supplies required. So, as a vantage-vantazhuvalny front of confusion, the development of indicators is carried out just for the incoming and outgoing goods flows with the most recent orders, given the maximum values.

Visually, you will need a number of posts to attract and upgrade. For a large number of cars, you can come for extra supplies with an uneven supply. Dobova is the number of vehicles, when it comes to vantage point, just for the formula:

Na / t input = (V input / output × knequal. Input) / (Npall × Spall × Npall. A / t);

Na / t input = (120 × 1.4) / (1.2 × 0.96 × ЧЧ 22) = 6.6 ≈ 7 od.

Visually, you need a number of posts for processing the incoming goods flow:

Nvot input = (N a / t input × trazgr) / Tvhod;

N gate input = (7 × 0.75) / 4.5 = 1.2 ≈ 2 od.

Nowadays, there is a need for a number of additional posts. Dobova is the number of vehicles to come before the appointment:

Nа / t exit = (Vinput / exit × knequal. Vihid) / (Nzak × Szak × Nzak. A / t);

Na / t vihid = (120 × 1.8) / (0.6 × 0.96 × 10) = 37.5 ≈ 38 od.

A number of doors are required for processing the outbound commodity flow:

Nvot vikhid = (N a / t vykhid × totgr) / Twihod;

N gate wihid = (38 × 0.75) / 3.5 = 8.14 ≈ 9 od.

Also, all of us will need 9 doors: 7 sets of dock facilities (sectional gates, dock shelter, dock leveler) for servicing small vehicles and 2 sets of dock facilities (sectional gates, dock shelter, dock leveler) for servants Nowadays, it is necessary to have a lot of space and a lot of areas to attract / replace. Yak bulo is indicated in the last tribute, the attraction of the part to the goods is going to take place for the re-establishment of the transport and the hour of the acquisition of the part of the goods in the hour of the release of the automobile. To ensure that the process in the zone is secured without interruption, the hour of attracting the party to the goods will be taken into account by the new party. To secure the vikonannya robot for a given technologist mnіst of one post of attracting is guilty of allowing a one-time commodity obsyag, r_vniy two-time obsyagu goods in the body of vehicles.

With such a rank, it is necessary to have the space and area of the post for the warehouse:

Npall. Priom = 2 × Npall. a / t = 2 × 22 = 44 pallets;

Vpіem = Npall. Priom × Npall × Spall = 44 × 1.2 × 0.96 = 50.7 m3;

Sпріем = (Npa ll. Priyom × Spa ll) / kіsp. pl. Priom = (44 × 0.96) / 0.32 = 132 m2.

kіsp. pl. Priyom - kof_tsієnt vikorystannya area of the zone and priymannya. For the front rozrahunku accept kіsp. pl. Priom = 0.32. Having multiplied the removal of the value by the necessary number of postings for the promotion and acquisition of goods, it is necessary to take into account the necessary characteristics of the zone for processing the incoming goods flow:

Npall. priyom zag = Npall. input × Nvolt input = 44 × 2 = 88 pallets;

Vprіem zag = Vprіem × Nvolt input = 50.7 × 2 = 101.4 m3;

Sпріем zag = Sпіем zag × Nvorot input = 132 × 2 = 264 m2.

The technology of removal is similar to the technology of removal. Completed in the warehouse, the route is located in front of the gate. So, when it’s the hour of transfer to the forwarder, it’s about the hour of transferring the replacement to the body of the vehicle, it’s necessary to have a lot of area of the sector to be added through one gate of the warehouse:

Nzak. disgr = 2 × Nzak. a / t = 2 × 10 = 20 pallet-pieces;

Votgr = Nzak. discharge × Nzak × Szak = 20 × 0.6 × 0.96 = 11.5 m3;

Sotgr = (Nzak. Otgr × Szak) / kіsp. pl. otgr = (20 × 0.96) / 0.32 = 60 m2.

kіsp. pl. otgr - kofіtsієnt vikorystannya areas of zones and vidvantazhennya. For the front rozrahunku accept kіsp. pl. otgr = 0.32.

Visually, the necessary characteristics of the zone for processing the outbound commodity flow:

Nzak. otgr. zag = Nzak. otgr × N gateway = 20 × 9 = 180 pallets;

Votgr. zag = Vzak. discharge × N gate vikhid = 11.5 × 9 = 104 m3;

Sotgr. zag = Szak. otgr × N gateway = 60 × 9 = 540 m2.

For the zone of profit / loss, the most important indicators are:

N gate zag = 9 od.;

Npallet-m_sts priyom / otgr. zag = 180 pallets-min;

Vprіem / otgr. zag = 104 m3;

Sпріем / otgr. zag = 540 m2.

With a small column of 6 m, there is one gate in one opening. The diagram of the catching / lifting zone is shown in Fig. 1.

ZONE ZBERIGANNYA TA VIDBORU GOODS

Visually, the main parameters of the zone and selection and selection. It takes us an hour to transfer the goods to the warehouse, to pay the additional flow and to pay attention to the transfer of goods to the warehouse. Rozrakhumo need to be in the area of selection and selection:

Vstore = V input / output × knequal. keep × Tobor;

Vstore = 120 × 1.4 × 15 = 2520 m3.

Nowadays, it is significant that we are presented in our list of products for pick-up. Korobkov selection I will hand over, now, all articles of the fault are presented in the manual access zone. The options for the distribution of goods on the front pallet racks are displayed, and for the first tier of pallets, a boxy view will be carried out. The middle storage of the palette is set to half of the volume of the palette.

The formula for the value of the required number of palettes for our selection is as follows:

Npallet-m_sts keep = ((Vstore - (narticles × Npall × Spall) / 2) / (Npall × Spall)) + n articles;

Npallet-mіsts = ((2520 - (100 × 1.2 × 0.96) / 2) / (1.2 × 0.96)) + 100 = 2238 pallets-mіsts.

Apparently, the maximum number of tiers in frontal racks is possible when spaced 100 articles on the first tier:

Save the tiers. possible = Npallet-m_sts keep / n articles = 2238/100 = 22.4 tier.

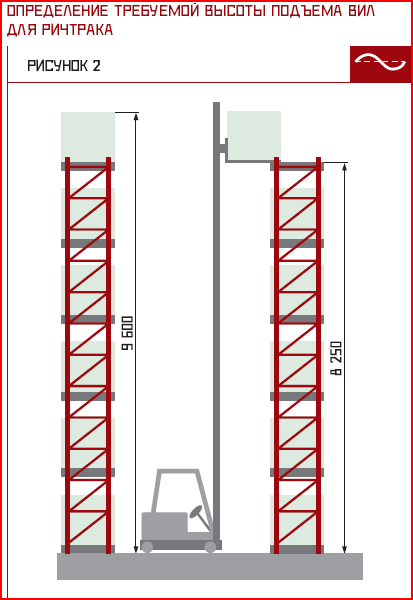

Obviously, such a number of tiers for the mechanized processing of commodity flows will not be necessary for us. Supposedly, it is seen from the view of the pidlogi to the bottom of the beam of the cross of the projected warehouse set to 10 m. The height of the goods on the pallet Npall = 1.2 m. I will look at the height of the rack, the height of the horizontal rack beams, the height of the technological gap above the skin pallet for the goods, and the space on the crossbar for laying the comunicat, 6 layering. Installation of pallets with goods will be available for reach trucks with a fork height of 8.6 m (Div. Fig. 2).

Visually, in the first approaching the area required for the selection and distribution of goods (div. Fig. 3):

Sstore = (Npallet-m_sts keep × Spall) / (Nyars keep x k_sp. Pl. Keep);

Sstore = 2238 × 0.96 / (6 × 0.33) = 1085 m2.

kіsp. pl. keep - the function of the registration of the area of the zone and of the selection and of the vidboru. For the front rozrahunku accept kіsp. pl. keep = 0.33.

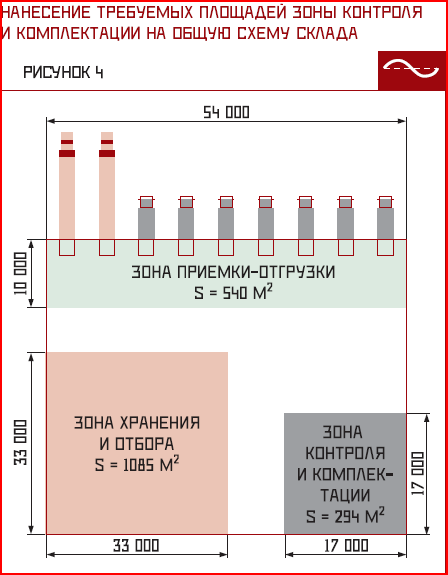

ZONE CONTROL AND SET

To designate the area of \ u200b \ u200bzone and control and kitting, we need to develop a number of items in the kit. The leather inspector-picker reconsidered the correctness of the selected replacement, the brand of the box with the goods, the delivery of the necessary documents and the contribution to the first replacement box, consolidation of the box of one replacement for the transfer for the transfer to the transport zone. Supposedly, the average productivity of the warehouse picker-controller is 4.1 replacement for a year. With such a rank, a number of inspectors-pickers are needed and, as a matter of fact, in the complete set, it is possible to depend on the formula:

Nset = V input / output × knequal. vihid / (Labor × qcompl × Nzak × Szak);

Nset = 120 × 1.8 / (8 × 4.1 × 0.6 × 0.96) ≈ 12 chol. = 12 posts

The middle area of the post for control and assembly of the warehouse is close to 24.5 m2 (a diagram of the possible layout of the assembly post is presented in the article by Andriy Ivanov "Another stage of the design of the warehouse", "Warehouse technologies" No. 3, 2007. - Editor's note), at For the whole skin post, 4 pallets should be re-stitched with replacements: two before processing and two pieces of paper.

Headquarters area for control and assembly of the warehouse (div. Fig. 4):

Sstore = Nset × Spost set = 12 × 24.5 = 294 m2.

The range of zones and control and completeness of the warehouse:

Npallet-m_sts = Nset × Npallet-m_sts post counter = 12 × 4 = 48 pallets-m / s.

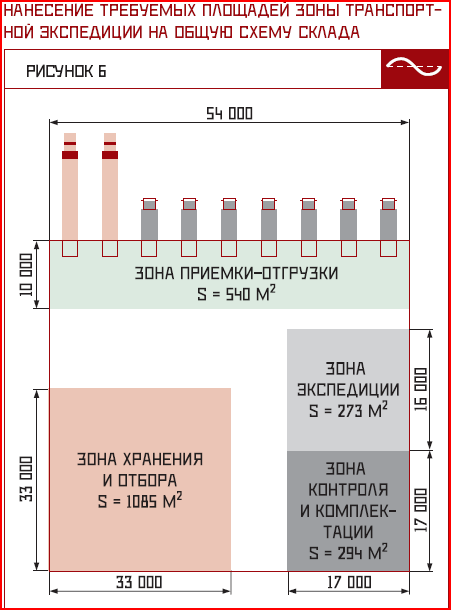

TRANSPORT FORWARDING AREA

Updates are available from 8.30 am to 12.00 pm, from now on, all changes in the repairs are completed and distributed in the transport expedition zones until the end of the working day, before the day of renewal, and the entire zone is responsible for the distribution

Vexp = V input / output × knequal. vykhid;

Veksp = 120 × 1.8 = 216 m3.

Npallet-mіsts exp = Veksp / (Nzak × Szak) = 216 / (0.6 × 0.96) = 375 pallets-mіsts.

As soon as all of the substitutions for pits are in one tier, we will need new areas:

Sekspedіtsіі = Npallet-місць EXP × Szak / kіsp.

pl. exp = 375 × 0.96 / 0.33 = 1125 m2.

With the help of the economy of warehouse areas in the area of expedition, you can add shelves. Number of tiers accepted N tiers exp = 4 pcs. With a wide range of robots for spaced out and picking up the replacement in the area of transport expedition, we can get an electrical outage using a fork lift of 3.5 m (div. Fig. 5 on side 14).

Sekspedіtsіі = (Npallet-mіsts exp × Szak) / (kіsp. Pl. Exp × Nyarusov exp);

Sekspedіtsіі = 375 × 0.96 / (0.33 × 4) = 273 m2.

kіsp. pl. eksp - kofіtsієnt vikorystannya area zoni ekspeditsії. For the front rozrahunku accept kіsp. pl. exp = 0.33.

We racked up the necessary capacity and area of technological zones for the warehouse (div. Fig. 6 on side 15).

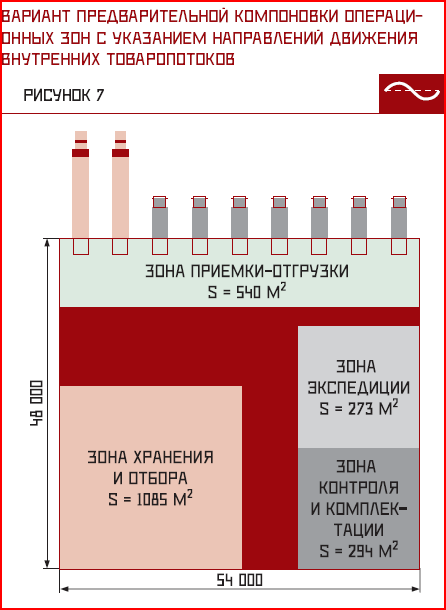

According to the results of rosrahunks, a table of necessary logistic efforts is put together in a warehouse (div. Table 1). Slide means that the front opening of the back area was carried out without the central passage through the zones. The back area of the central aisles for the front lines is 15-20% of the total area of the operational zones. With tsom Zagalna square the warehouse is now close to 2600 m2. An alternate version of the layout of the representation zones in Fig. 7.

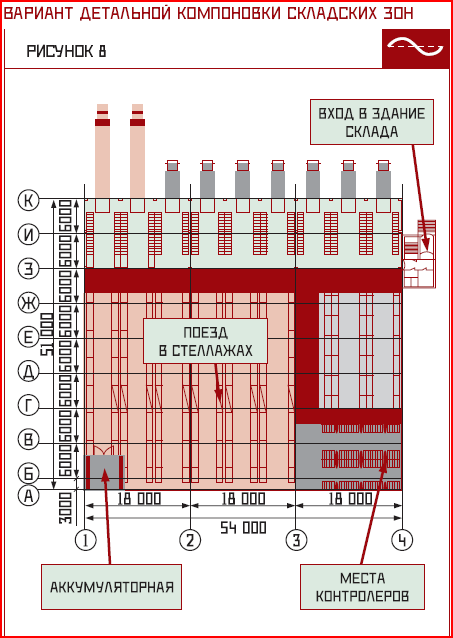

More details for sale in the WAREHOUSE

We will go over to the detailed prod- uct warehouse. At the end of the stage, it is already possible to rotate the columns, the appearance of additional primitives, technological capabilities, which are presented to the victorious possessions of that technology. In addition, in the clean version of the area of the zones and the warehouse as a whole, it can be paid to the deyakim snakes (Div. Fig. 8). The actual characteristics of the technological zones are indicated in table 2.

It is imperative that it is recommended to carry out the development of the component solutions on a varied basis on the basis of the more basic logistic / economic indicators and the choice of the most optimal variant.

ROSRAHUNOK CONSUMPTION FROM RESOURCES

For a more logical design, we will need to introduce additional data and interchange.

Razvantazhennya vehicles go for help navantazhuvachіv from wash one navantazhuvach for one rozvantazhuvati car.

Indicators of productivity of PTO (reach trucks, Electrostacker) at vison of internal warehouse operations:

- distribution of accepted pallets on shelves QPTO size = 20 pallets / h;

- transfer of goods from the upper tiers to the lower (growth) QPTO change = 26 palls / h;

- transfer of goods from the zone of the set to the zone of expedition QPTO set = 24 pall / h;

- relocation of goods from the zone of expedition to the zone of admission QPTO exp = 24 palls / h;

- productivity of picking boxes at picking boxes qselection = 2.2 zak / h.

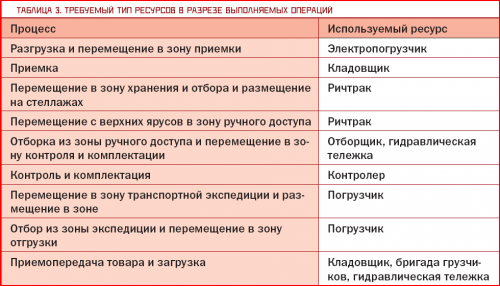

Technological operations based on the values of the rear guidance resource in Table 3.

CONSUMPTION OF RESOURCES WHEN CONDUCTED BY ROBIT FOR RISKING AND RECEIVING GOODS

For the accepted technology of processing the incoming commodity flow, one machine will be removed by one navantazhuvach, at the same hour the machine will be taken out of all parts of the goods by the salesman.

Main applications and technological zones and warehouse

The solution to the problem and the selection of the warehouse complex is allowed to go to the date of the offensive food - the optimal area for the warehouse and the planning of warehouse facilities. On the offensive little one is presented zagalna schema a warehouse with retail and automobile transport routes, on which the main types of applications and technological zones are specified and a warehouse (div. drawing "Scheme of a warehouse").

The planning of warehouse facilities can vary in fallowness in view of the fact that the warehouse is used, which can be used for new products, special features of warehouse technological processes, a typical scheme for the collection of vantage flows at the warehouses of some other officials. However, if planned at the warehouse, it is possible to see the onset of the main applications and technological zones:

Attribution of the main virobnichannel(abo main attitudes) To be victorious for the collection of products, as well as for the sale of a whole number of warehouse operations.

ramp It is a platform specially designed for carrying out vantage and vantage robots with specific types of transport. So, in the presented diagram on hall ramp it is possible to carry out the vantage, car ramp loading on vantazhny motor vehicles for completing parts of the direction.

expedition vikorystovuєtsya for a short-hour zberіgannya vantazhіv, who arrive at a working hour at the warehouse, for example, in holy, wihіdnі or nіchnі years. in the right expeditions to be designated for a team-hour selection of vantage parties of revision, in order to clear the supply of transport means for carrying out vantage operations.

dilyanka priymannya Designated for converting products, acting according to quantity and quality. on dilyantsi set There is a complete set of vantage parties for revisions, as long as there are new ones.

zberigannya zone- the main technological zone of the warehouse, which possesses universal or special possessions for the collection of goods. The goods in the zone must come from the expeditionary expedition, the dilyanki to take in, or bezposeredno from the zaliznichnoy ramp. Smells grow on the racks, or in the first warehouse, and then go to the delivery of the complete set, in the forwarding expeditions, or without the middle to the car ramp for referral to the customers. The middle zones can be seen around the inner zones for the collection of singing groups of goods (food, industrial, state, etc.)

additional services It is recognized for the collection of food items, empty containers, warehousing tariffs. In the case of cikhs, repairs can be carried out during the turnover of tar.

V additional technical features It is possible to re-install machine windows, ventilating chambers, repairing mains, komori, recharging accumulators and batteries.

nareshty, administrative-butt-priming include offices, offices, misconceptions and receptions.

Malunok "Scheme of a rozpodilny warehouse"

DEYAKI CHARACTERISTICS І INDICATORS OF ROBOTS IN THE WAREHOUSE

For the development of a brown area warehouse, it is necessary to know the characteristics of the warehouse and the planned indicators of its robots. Until the eighth day, the warehouse must be delivered, the corridor and the back area, the throughput of the building and the turnover of the warehouse. It is easy to see the indicators

І vantazhoobіg warehouse

For a warehouse, there is a maximum number of vantages, which can be adjusted for the storage at a given warehouse. Vantazhі zzvychay calculated in tons. For example, the storage capacity should be 3000 tons (E = 3000 tons). This means that up to 3000 tons of products of a singular type, for example, food and industrial goods, can be distributed in warehouses.

The most important indicator of the collection of belongings is the number of packages that have been processed into warehouses during the singing period. For example, the warehouse can be supplied with 100 thousand tons per day (Q = 100,000 tons / day). This means that 100 thousand tons of vantages were processed at the warehouse for the rik bulo.

On the basis of the warehouse rework, the warehouse operations from the reception and the revision of the vantages, the distribution at the warehouses for the acquisition, the collection, the assembly and the revision to the removal, which will be approved in total warehouse technological process.

A leading indicator of the values of EіQ is the middle term for the collection of vantages:

t cf = D p E / Q

de -kofіtsієnt vikorystannya otnosti warehouse, D p-number of working days at roci, d.

Undoubtedly, the warehouse is not expected to be 100% victorious. As a rule, only a part of the warehouse will be victorious, and only the part will be less than one. Until then, how to rozrahovuєtsya efficiency, we will turn three more piznіshe.

Korisna area of the warehouse

The main function of any warehouse is the selection of products. For the purpose of establishing the central function, there is a zberigannya zone, de-roztashovuske storage facilities, in which products are secured. That part of the zone zberigannya, the yak is occupied by the warehouse possessions, I will name it cinnamon area warehouse.

Find out the different methods of roasting the coriander area of the warehouse. Vibir methodology to lay down according to the type of warehouse and type of product, which can be stored, as well as design features and storage technologies. Two butts are visible.

Butt 1. Amount of warehouse for the selection of important metal virobes (metal workpieces, tools, metal virobes, parts, universities, etc.) To be 5000 tons. by the formula:

S pidlog = E / = 5000/2 = 2500 m 2,

de E - the number of the warehouse, t; - it is permissible to navantazhennya to the warehouse pidlog, t / m 2.

Coefficacy is determined by the design features of the warehouse. In the case of extravagant households, for example, in stores, for a start-up period, they vary within = 0.6 ... 1.0 t / m 2. , vuzli і ін.), Tsei kofіtsієnt syagaє values = 3.0 ... 4.0 t / m 2.

Butt 2. The capacity of the warehouse for the collection of goods with a wide range of living is 2000 tons. The average volume of the vantage is 0.5 t / m 3. The vantage of the vantage is stored on the shelves of the ST-2M-II brand. Rack sizes are stored 412017054000 mm. The coefficient of storage for the volume of the rack during the zberiganny vantage in the pods should be set to 0.64. Todi is the area of the warehouse, it is occupied by the shelves, the insurance is given for the formula:

S pidlogu = E / (H) = 3000 / (40.50.64) = 2344 m 2,

de H is the height of the vantage stacking, m; - average vantage capacity, t / m 3; - kofіtsієnt zapovnennya volume of the rack (capacity of the stowage).

Zagalnaya area of the warehouse

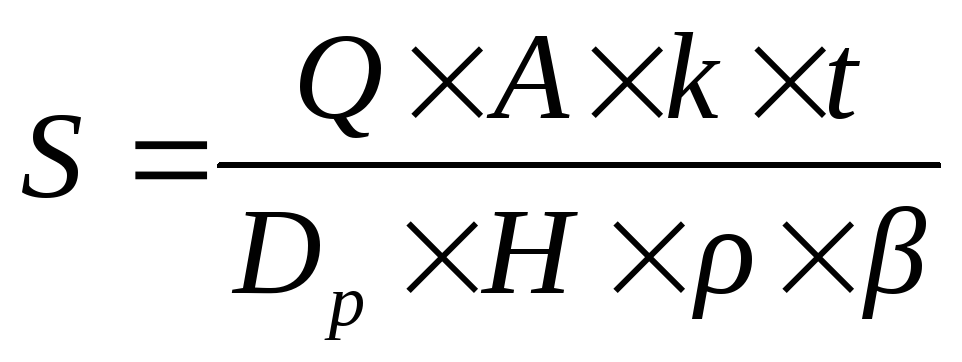

pid behind-the-scenes warehouse It is a bit of a reason for the basic distribution of applications, including the housing and equipment, the right and the right forwarding, as well as the area of passage and passage through the racks and other warehouse possessions. In a specific skin type, the size of the storage area is associated with specific plans for the storage area. So, for example, the area of the upstream and downstream majdanchiks can be visually significant on the skin from the onset of two formulas:

de Q- rychny vantazhobіg warehouse, t / rіk; A - part of the vantazoobіgu, scho pass through the given technological zone (A = 0.2 ... 1.0); k- coefficient of unreasonable vantage (k = 1.2 ... 1.5); t - middle triviality of transferring the vantage to the technological zone (up to 2 days); D p - number of working days for a period; - permissible vantage on pidlog, t / m 2, H- height of vantage, m; - average vantage capacity, t / m 3; - kofіtsієnt zapovnennya obsyagu shelving, for example, stowage capacity.

Pid vantazhoob_gom warehouse costs sukupniy obsyag vantazhu, which is needed or vibrated from the warehouse for a singing period of an hour.

With the appearance of a function A in the formulas of the Viclikano team, not all of them pass through the reception and the right expeditions, the distribution of the reception and the complete set, and only the deyak of the chastin.

The width of the passageway between the racks is from 1.5 to 4.5 m, the width of the passageway - from 0.7 to 1.5 m. the yak is guilty of folding 15-20 cm.

When approaching rosrahunks, you can vikoristovuvati formula:

S zag = S pidlog / = 2500 / 0.4 = 6250 m 2,

de S zag - zagalnaya area of the warehouse, m 2; - kofіtsієnt vikorystannya area of the warehouse.

Building throughput and warehouse turnover

One of the most important parameters in the warehouse is the middle term for the collection of vantages, which is based on the formula:

de t i - hour of staying at the warehouse, days; q i - volume of the i-th vantage, t; Q- sukupny vantazhob_g warehouse for singing period, i.e.

Supposedly, five parties passed through the warehouse with a singing period. Obsyag vantazhiv and hour sberіgannya is indicated in the table below:

|

№ p / p |

Obsheg vantage, t |

Hour of zberigannya, days |

q t |

The average hour of vantage in the warehouse should be set: t avg = 30250/410 = 7.38 days. Knowing the value of this indicator, it is possible to develop the throughput of the building and the turnover of the warehouse for the singing period.

Warehouse throughput

F = E / t cf = 3000 / 7.38 = 406.6 t.

At the opened stock, the capacity of the warehouse should be close to 400 tons for additional storage. Apparently, the warehouse complex is guilty of the necessary resources for securing such a throughput building. For resources, there is a warehouse staff, warehousing, for example, navantazhuvachi, as well as the necessary technological space, so that operations will be carried out to receive and release vantazhiv.

Warehouse turnover (for example, monthly turnover) is based on the formula:

P pro = D p / t cf = 30 / 7.38 = 4.07,

de D p - number of working days per period (for example, month), days.

Koefіtsієnt vikorystannya mіstkostі warehouse viznachaet for the formula:

= Q t avg / (D p E) = 100,000 7.38 / (365 3000) = 0.67.

This rank, zapovnennya warehouse products become in the middle 2/3 of the whole warehouse.