Classification and characteristics of gross ores. Vidi zaliznykh ore - zagalny characteristic of iron ore

Zalizna ore is a particularly mineralized solution, including zalizna, also spoluky. Ore vvazhayut steel in a wide range, if you want to take revenge on the element in sufficient expenses in order to be economically viable.

The main type of zaliznoy ore is magnetic zaliznyak. Win to avenge 70% oxide and oxide salt. Qia ore is dark abo siro-steel color. Magnetic zaliznyak on the territory of Russia is added to the Urals. Zustrіchaєtsya winn in nadrah gir Magnitna, Visoka, Grace and Kachkanar. At the time of Sweden, you know in the districts of Falun, Dannemora and Gellivar. The United States has a Pension and Norway has Arendal and Persberg.

In black metallurgy, gold ore products can be divided into three types:

Separated zaliznu ore (with a low volume of zaliznu);

Aglorudi (from the middle of the wedge);

Okatish (sira zalizovmіsnykh masu).

morphological types

For the sake of safety, such loads of gold ore can be used, as you can place more than 57% of the deposit in your warehouse. Before single ores, it is brought in, in some more than 26% of saline. The ore was divided into two morphological types: line and flat-like.

Loss of line-type ore є wedge-shaped ore in the zones of viginous and earthly fractures. The Danish type is distinguished especially by a large amount of gold (from 50 to 69%), ale sirka and phosphorus in such ore is found in a small amount.

Flat-like pads are formed on the tops of layers of golden quartzites, which represent a type of bark of vivitryuvannya.

Zalizna ore. Stuck and vidobutok

Bagata zalizna ore stasosuvannya should be found to deny the chavun and in the head id for the high-melting point in the converter and open-hearth production, or specifically for the renovation of the zaliza. There is a small amount of habitat yak natural farba (ocher) and a weighting agent for clay drilling sums.

A large number of stocks of developed genera become 160 milliards. tons, and the amount in them is close to 80 milliards. tons. Zalizna ore is known in Ukraine, and the largest reserves of pure gold are in Russia and Brazil.

Obsyagi svitovogo vidobutku ore virostayut with skin rock. As soon as the ore is zalizna vidobuvayetsya in an open manner, the day of the field is in the fact that all kinds of technology are delivered to the people of the people, and there will be a car. The glibina kar'єru should be set in the middle, close to 500 m, and its diameter will lie in the peculiarities of the known family. For additional special possession, they add ore, store them on machines that are attached for the transportation of important vantages, and deliver them from the carriage to enterprises that are busy with the bulkhead.

In a limited way, it is possible to add ore to the small glybin... Well, you should lie on the bedside, to be brought to the mine. There is a lot of rocking stovbur, scho a big well with visible strengthening walls. At the other side of the road, there is a corridor, so called roadways. I know that ore is brought in, and when I know, little girls are brought to the surface for extra special possession. Vidobutok zaliznoi ore by this method is effective, ale tied with a suvor threat and vitrates.

The best method is to add ore. Yogo is called SRS or Sverdlovini gidrovidobutku. The ore grows from the ground in such a rank: to drill the top of the hole, lower pipes in it with a hydraulic monitor and crush the rock with an even stronger water jet, as it drifts to the surface. The vidobutok of zaliznoy ore is not baked by the method, but, unfortunately, it is ineffective. So go to get only 3% of ore, and 70% get out for the help of the mines. Along with the SRS method, there is a great deal of opportunity, but in the current version you will become the head of the state, who have turned the mines and kar'eri.

Power of gold ore:

Hardness: 6

Warehouse: SiO2 Al2O3 Fe2O3 K2O Na2O

Miscellaneous: For the tribute of the US Geological Service, Ukraine has the most developed reserves of gold ore, at that time Russia and Brazil have to go for a lot of ore reserves in order to be stored in now.

Functional victorian: zaliznі ore They are developed according to the mineral warehouse, instead of the corridor, brown and wicked houses, by the minds and by the promiscuous authorities. Fallow chemistry warehouseїх zasosovyut for whiplash chavunu in a natural view or write a bagachennya. Salt ore, which can be used for processing steel, is to blame for the origin of the ore in the necessary proportions.

Zalizna ore Description:

Zaliznaya ore is called natural mineral approval, which reveals zalizo in great numbers and such cheeky spas, which the hero of the day is possible and docile. Mineral minerals є: magnetite, magnomagnetite, titanomagnetite, hematite, hydrohematite, goethite, hydrogetite, siderite, chlorite zalizist. Zalizni ore razriznyayutsya on the mineral warehouse, instead of the gale, brown and shkidlivny houses, minds and industrial authorities.

Zaliznoi Rudi's stasis:

1. Zalizna ore yak dzherelo zaliza.

Zalizna ore is a wide and wide spread dzherelo zaliza (Fe), I want to take revenge less than 50% zalizo, more less than a smut zerlo zaliza. Historically, a large part of the British Gulf has become from gold ore, but now it is rather rare to be victorious with a great deal.

2. Ceramics

Zalizna ore is vikorized as a component in deyakiy keramitsi. Sin Mason Mіl potter) won a patent for "Freemason Zalizna ore China" in 1813. By the 1970s porcelain of zaliznaya ore became popular.

3.In Budivnistvі

Stone can also be used as an alarm material. Attach to the parish church at Kirby Bellars in Leicestershire.

The SBM Company has been making a variety of green ore pellets in China, including Shock pellets, Cone pellets and Mobile pellets.

Cone shot mill for gold ore є with one stone crusher with the highest efficiency. In common with other crushing equipment, cone pellets of gold ore with high efficiency in crushed gold ore, high productivity and low exploitation of vitrate.

Mobile pellets of gold ore are crushed, according to the new idea of crushed, which expands the understanding of the great crushed and other crushed. The SBM company has been engaged in projects that have been thoroughly developed and manufactured in shotguns since 1998. One of the last one companies in shotguns є distribution of absolutely new shotguns - Mobile Shotboxes. Mobile shot machines include Mobile Jaw Shot, Mobile Rotary Shot, Mobile Cone Shot, Mobile Crawler Shot, a nominal productivity range of 600 t / year. Our perezuvny crushing plants for gold ore will ensure the optimization of production and reduction of costs. The mobile crushing plant has a higher productivity, the ability to handle large pieces of food and compactness when transporting. Mobile shot maker is ideally suited for crushing materials of medium hardness, such as vapnyak, saline ore and mineral-based ore, pulp, asphalt and concrete.

Zalіznі ore is a girskі breed, so to take revenge on zalіzo, moreover, in such a bunch, ore can be easily processed. In nature, there are close to 20 minerals with a high, large salinity (23-72%). Zalizo in the ore is found in the viglyadi oxides or salts, which are found in the girskaya rock. I will become fallen, in which there is a zalizo, I will develop chotiri vidi of zaliznyh ores.

Buri zaliznyak avenge Zalizo near the hydrous oxide 2Fe2O3-3H2O. Kolir ore zhovto-bury. The ore is bidna with zalizom (from 35 to 60%), and the grains and phosphorus, navpaki, to revenge more, lower in the ore. The ore is easy to change. Most of the ancestors are found in the Urals (BAKAL ore with a very large salt, mayzhe without houses and phosphorus). large reserves brown zaliznyak in a powder-like viglyad є on the Kerch pivostrov. There are also Tulsky and Lipetsk ancestors, the ore of the Kolsky pvostrov, Togaysky zaliz-ore basin.

Chervoniy zaliznyak revenge Zalizo at the sight of Fe2O3 oxide. Ore of chervonogo koloru, vm_st zaliza 55-60%. Tse one of the smallest zaliznyh ores; It is easy to renew, to take revenge on a little bit of water and phosphorus. Naybagatshi genus of red zaliznyak is found in Crooked Rose. There are large reserves of chervony zaliznyakє also in the region of the Kursk Magnetic Anomaly.

Magnetic zaliznyak to replace Zalizo at the sight of Fe304 oxide. Black colora ore, 45-70% vm_st zaliza. Price for the most abundant zalizom ore. Vona has a magnetic power, she is smart, to be renewed with practice. Zalyaga head rank in the Urals - in the mountains Magnitna, Visoka, Blagodat. Not long ago, the development of a genera of magnetic zaliznyak in the Togai steppe in Kazakhstan.

Sparovy zaliznyak take revenge on Zalizo at the sight of FeCO3 salts. Qiu ore is called siderite, or bog ore. Vona bidna zalizom (from 30 to 45%). Lay a sparry zaliznyak growing up in the Urals in the area of the Bakalsky clan

Complex zalizni ore revenge, crim zaliza, and other metals (chrome, nickel, titanium, vanadium), put-Livan in the domain of swimming:

chrome-keleevi bury zaliznyaks of the Orsko-Khalilovsky genus make up 35-45% of zaliznya; 1.3-1.5% chromium and 0.3-0.5% nickel;

titanomagnetite, with 42-48% salinity; 0.3-0.4 / about vanadium and 4.5-13.0% titanium dioxide, vypubuyutsya in the Urals in the Kachkanarsky, Kusinsky and Pervouralsky genera.

Manganese ores become stagnant, schob grows instead of manganese in high-melted chavuns. Tsі ore myakі, rikhlі and hygroscopic. Zm_st to manganese oxide in them is 28-40%. Naybilsh is an important genus of high-grade ores (instead of manganese oxide 48-52%) є Chiaturskoe in the Caucasus, Nikopolske in Ukraine, near Achinsk in Siberia, Uraloazovskoe and Pivnichne in the Urals and in Kazakhstan.

In the process of blast-furnace smelting, in addition to gold and manganese ores, the vicorisation comes from: chavunniy scrap and shavings, no steel brucht.

Freeze flux in blast furnace for alloying of empty rock and ash of firing into slag. For robotic blast furnaces on coke, vapnyak (CaCO3) is the head. There are basic oxides in the empty rocks, and acid flux - quartzite - is stagnant.

The coke is used for blast furnace smelting. Metallurgical fire is guilty of the mother of advances in quality: high heating value, good quality, porosity, low ash content and minimal energy consumption. Coke is made even more vimogam. The heat of burning coke is 5600 kcal / kg, which is used to melt 98% of the sweet chavun. Coke to wash off kam'yanogo vugillya at heating up to 950-1000 ° without access to the oven in special ovens. When there are a lot of vugіllа, you can see leaks of speech, and then a part of it gets lost in solid and porous coke.

Every day, the battery is stored in 50-70 high-capacity chambers, with an average of 18-20 m, and 12-16 tons of coke are dispensed from them. The triviality of the coking process is close to 12-15 years. One ton of coal can be used to trim 750-800 kg of coke and 300-350 m3 of high-calorific gas.

We use coke to bury Kuznetsk, where we need to take away 0.5-0.6% of sirka and 12-13.5% of ash.

One of the most effective private coke substitutes in the blast furnace is natural gas. I don’t change the part of it 2 rubles. for 1000 liters, that is, in dozens of times lower than the rate of coke.

sucking natural gas when you reduce the cost of the chavun, so you can save from 10 to 15% of coke.

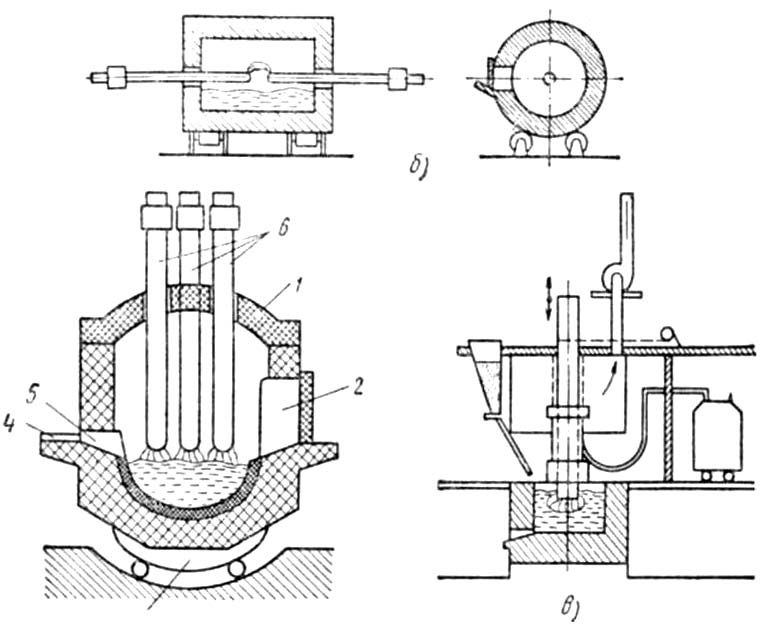

5. Attach a blast furnace and a robot

Domain pich- blast furnace) є mine food without interruption. Vona has the shape of two truncated cones, folded in wide arches, between which there is a cylindrical part, which is called a steaming.

Chavun is melted from gold ores in special furnaces called blast furnaces. The process of rejecting the chavun from the hard ores is called a blast-furnace process.

The domain can provide a great number of special attachments and mechanisms, which will ensure uninterrupted operation of the process. Most of the mechanisms are automatic.

1-skip; 2-zipnoy device; 3-domain p_ch; 4-tuyeres open; 5 chavunna lotka; slag whip; 7-power-up; 8-gas purification attachments; 9-dim pipe

The sum of ore, coke and flux is prepared in a singular proportion for entangling into the domain of the coke. Such a sum is called a charge. Special pidyomnik - skip 1 to move along the stolen roads, delivering the charge to the upper part of the blast furnace, the sound through the boiled device 2 goes to pich 3.

To keep up with intensive mining, you need a lot of coke to get coke. It is fed into the food through special openings 4 in the lower part of the oven, which are called tuyeres openings. After breaking through a high stove of the charge, it penetrated into the parts of the oven, and there was also a sufficient amount of sourness for burning all the fire, when it was blown into the food with a grip of 1-2 atm. Sometimes it is heated to temperatures of 600-800 °, so as a great amount of cold weather is blown in, it lowers the temperature in the middle of the furnace, as a result of which the ore smelting process is better.

Pidigriv will appear in the air heaters 7, as there will be order from the blast furnace. Povitronagrivachi scorched by blast-furnace (blast furnace) gas, which goes out with the viplavtsi chavun. The blast-furnace gas is cleaned in front of the saw in special gas-cleaning annexes 8. The gases from the air heaters are seen through the dim pipe 9.

Otrimaniy in the stove the rydky chavun goes down into the lower part, the stars are periodically released through the opening 5, called the chavunnoy vichkom. In the special ladles of the great city, the chavuns from the blast furnaces are transported to the steel-making shops for processing into steel, or to the filling machine for cutting off the chavunnich ingots.

Empty rock, flux and ash of firing set in the oven a rare slag, like a little wag, lower chavun, and then roztashovuyutsya over a rare chavun. The slag is let out from the furnace through the slag taphole 6 and is sent for recycling that forgiven vikorstannya in the quality of the industrial material or into the slag inlet.

The domain will work without interruption according to the principle of prototyping: all the materials are tied up from the top, step by step they go down, being converted into chavun and slag, and the gases heated in the lower zone of the furnace, will be called

Pich maє zovnіshnyu steel shell, yak called a casing, and internal masonry, or footer. The lining is to blame for the fast repair of the wear and tear through the rubbing without interruption, dropping in a hundred different materials, vitrifying for high temperatures, not melting or causing deformations. To that for the future it will be stagnant a viscous congestion (chamotna) tsegla.

6. Steel production in converters

![]()

KISNEVIY CONVERTER with top blowing. 1 - steel casing; 2 - concave lining; 3 - kisneva tuyere; 4 - filling with flux; 5 - light additives; 6 - rychka; 7 - kivsh; 8 - procurement; 9 - drit; 10 - pipe is seamless; 11 - bloom; 12 - beam; 13 - plate steel; 14 - sheet procurement (slab); 15 - rolled sheets.

A sour converter with an upper blowing є a pear-shaped vessel (with an open upper neck) with a diameter of approx. 6 m and a height of approx. 10 m, veneering from the middle of magnesia (main) whole. Qia futuruvannya showcasing about 1500 heats. Converter for securing bichy pins, fastened in the supporting rings, which allows you to screw it up. At the vertical position of the converter, the throat is located under the knitted hood of the dimovivid stone. Bichne vypuskny opening, apparently from one side, allowing the release of metal into the slag when spilling. At the converter shop, charge the converter є the sealant spill. The ships are transported in the great buckets of the Ridky Chavun from the blast furnace, and in the steel bunkers there is a lot of metal to be stored. The whole chain is transported to the converter by an overhead crane. According to the first bik of the converter of the disassembly, the pouring spill, de є reasonable volume for melted steel and bulk transport for transporting it to the filling site.

Before the cob of the sour-converter process, the converter should be pushed towards the entangling spill and through the neck to boil the metal. Then pour the ferrous metal from the blast furnace into the converter, then close 4.5% in coal and 1.5% silicon. Before the metal is desulfurized in the ladles. Turn the converter at a vertical position, introduce a water-cooled lance from the top and turn on the acid feed. The carbon in chavun is oxidized to CO or CO2, and silicon - to SiO2 dioxide. For the "tichtsi" (zavanazhvalnogo tray) add a vapo for the approval of the slag with silicon dioxide. Slag contains up to 90% silicon, which can be found in chavun. Nitrogen in the finished product began to decrease significantly, and the production of nitrogen was greatly reduced by the CO. Approximately 25 minutes later, pull back, convert the trocha converter, select a sample and analyze it. If necessary, you can turn the converter at the vertical position and insert a lance into the neck. If the warehouse and the melting temperature are determined by the specifications, then the converter is poured towards the pouring spill and through the external opening pour the steel.

7. Otrimannya steel in open-hearth furnaces

Martin process of breaking up in 1865 by French metallurgists father E. Martin and P. Martin. Martenivska food on the basis of robotic and semi-intelligent regenerative food. In the її melting space, gas-like burning or fuel oil burns. The temperature for the removal of steel in the molten mill will be ensured by the regeneration of the heat of the food gases. The working space of the melting furnace is surrounded by the bottom of the bathtubs; above - crypts; from sides - front and back walls; from the ends - heads. At the front stage of roasting, through yak in the supply the batch and additional materials (during the melting process) are filled in, and also to take samples of metal and slag, to see the slag during dephosphorization. The windows are closed with shutters with oglyadny openings. I am ready to pour the melt through the opening, rostashovane in the back end on the lower level of the bottom. The holes are scored with low-baking non-baking materials.

Regenerators are installed in the gas and water systems for greater recovery of the heat from the outgoing gases. Regenerators of the viconani at the viglyadi chambers, fitted with a nozzle with a cone. The principle of heat recovery from the field is that the nozzle of one steam regenerator heats up to 1250 - 1300 ° C for one hour and enters the furnace with gases. Then, behind the additional valves, the regenerators change automatically. Through one of the heated regenerators in the working space of the oven, supply of food is supplied, through the other - gas. Pass through the nozzle, the stench heats up to 1100-1200 C. During the whole hour, the steam of the regenerators is heated, accumulating the heat of the gases, which comes in. When the nozzles of the regenerators are cooled down to the set temperature, the valves are automatically mixed again.

8. Rejection of steel in electric furnaces

Smelting in electric furnaces a number of reloads before melting in converters and open-hearth furnaces. The higher temperature allows the preparation of strongly basic slags, introducing a large number of fluxes and reaching the maximum visibility from steel to gray and phosphorus. For melting in an electric furnace it is not necessary to turn; the oxidizing capacity of the furnace is not very high, because the amount of FeO in the bath is insignificant, the steel goes to finish the oxidation and is strong. At high temperatures in the furnace, it is possible to trim alloyed steel with refractory elements: tungsten, molybdenum, etc.

Outstanding materials for smelting in electric furnaces are steel brucht, zalizna ore, scale. The overbearing open-hearth chavun is used only for steels with a high carbon content, and more often than for those with a low carbon content.

Yak flux in the main furnaces zasosovovyut vapno, and in sour furnaces - quartz sand. Fluorspar, bauxite and chamotniy bey are used for the distribution of the main slags; For the oxidation of steel, small ferrous alloys, use complex deoxidizers (AMS, 10% silicon, manganese and aluminum, silicomanganese, silicocalcium).

All materials that are stored in an electric stove, if they are dry, will not be damaged, they will not be found in any form of distribution.

All materials that are stored in an electric stove, if they are dry, will not be damaged, they will not be found in any form of distribution.

Electric furnaces for melting metal are divided into three types : Furnace support, arcs and induction.

For smelting, they began to stand in the main arc and induction furnaces, and in the furnaces, the support was melted with alloys of color metal.

Arc furnaces The most widespread in the industry, such as the adjustment and operation of the awkward, the efficiency of the coriander is high, and in addition, they can be used for the production of high-quality steel and alloys. In arc furnaces, the electric power is transformed into the heat energy of the arc, as the charge is transferred to the melting charge for additional vipromyuvannya.

Induction ovens It is used for high-melting of high-alloyed steels and alloys with low volume of carbon, as well as for the production of thin shaped casting by special methods (for high-melting models, with a vice, etc.).

Electroslag steel remeltingє an absolutely new method of rejecting high-quality light-alloyed steels, including high-grade steel. Winning of breakdowns by the Institute of Electric Welding Im. Є. O. Paton of the Academy of Sciences of the URSR.

The essence of this pole is in the fact that the hotties from steel, taken from the steel in the ovens, are recycled on the electrodes for the purpose of re-melting them in the electro-slag ovens. The melting of electric rods is not for the heat sink of the electric arc, but for the heat sink, which is seen in the ball of molten slag, serving as a support when passing through a new electric stream. The principle of electroslag remelting is even simpler. Electrode-ingot 1 (Fig. 3) with a diameter of up to 150 mm and from 2 to 6 m is introduced into the middle water cooling crystallizer 2, which is an empty cylinder. To the bottom of the crystallizer of attachments piddon 5 with a fuse 4 - a washer for remelting steel. An electrical conductive flux with a powder of aluminum and magnesium is poured onto the bait. At the gap between the hot-electrode and the crystallizer wall, fire up the working flux 3, which can be stored in Al2O3, CaFe2 and CaO.

9. Progressive ways to reject steel

One of the progressive ways to reject folding and high-grade steels is electrometallurgical: melting in electric arc and induction furnaces.

Steel is especially high-yielded for vacuum electric furnaces, as well as for electro-slag, plasma remelting, and electronic exchange smelting.

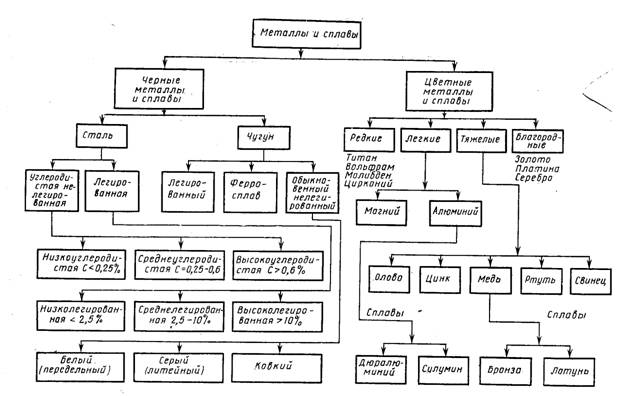

10. Home office about metals. Classification of metals.

Metals are materials of crystal structure, as they may have a low specific power: metal blisky; high electrical and thermal conductivity; positive temperature coefficient of the electrical support; electronic communication; with normal minds, perebuyut in a solid stanі (vinyatkom є mercury).

per zovnishnim viglyadom threw on black and color. Up to black metals, there are gold and alloys on the basis of metal, while metal is taken up to colore ones.

Black metal, vicarious from the state-owned goods, represented by two metals: steel (alloy of gold with carbon, with no more than 2.14%) and chavun (alloy of gold with carbon, with 2.14% of the rest).

Chavun melts from gold ore in blast furnaces.

Steel otrimuyut with a chavun a path of vipalyuvannya s ny excess in a sour povitrya coal.

11. Atomic-crystalline budova metal.

Due to the atomic-crystalline structure of the mind, instead of the rosetting of atoms, which is clear in the crystal. The crystal is composed of atoms (ions), rosted in the singing order, which is periodically repeated in three types.

Crystals have not only the near, but the distant order of the atomization, i.e. the order of the loosening of the particles in the crystals is saved on the great crystals of the crystals. For the description of the atomic-crystalline structure, one cries out to the understanding of the spacious abo-crystalline lattice.

The crystal lattice is a clear spacious grid, at the universities where atoms (іon) grow, and metal (solid crystalline tilo).

The most popular crystal, which gives a statement about the atomic structure of metal in all society, having named it elementary crystalline midges.

12. Power of metals and alloys

Prior to the main mechanical powers, carry out:

mіtsnіst

plasticity

hardness

Mіtsnіst - goodness to the material to repair the operation for the purpose of repairing it.

Plasticity is the building of material to change its shape and size according to the call forces.

Hardness is the solidity of the material to repair the penetration into the new body.

Physical power

Prior to the physical authority, it is necessary to carry out:

proficiency

melting temperature

heat conductivity

electricity

magnetic power

Colir - the quality of metal in vidbivat viprominuvannya with singing dyes. For example, mid-corn-chervony colir, aluminum - medium-beige.

The proficiency of metal comes from the quality of the material to the same size. For the sake, they started to play on the lungs (less than 4500 kg / m3) and important.

Melting temperature - the temperature at which metal is transferred from the solid mill to the metal. For melting temperatures, they develop refractory (tungsten - 3416 ° C, tantalum - 2950 ° C and in.) And low-melting (tin - 232 ° C, lead - 327 ° C). In CI units, the melting temperature is in degrees Kelvin (K).

Heat conductivity - the ability of metals to transfer heat from more heat up to less heat. Great heat conduction may be medium, medium, aluminum. In CI units, the heat conductivity is the mass W / (m · K).

The quality of the metal conducts the electrical system to evaluate two different characteristics - electrical performance and electrical support.

Electricity is assessed in the SI system in Siemens (Cm). Electroopir rotate in Omasi (Ohm). Good electrical wiring is required, for example, for conductive wires (they are ready for media, aluminum). When preparing electric heaters and stoves, it is necessary to fusion with a high electric support (with nichrome, constantan, manganin). With temperature adjustments, the electrical conductivity will change, and with lower temperatures, it will change.

Magnetic power rotate in the building of metals magnetized. With high magnetic powers, volodyut zalizo, nickel, cobalt and ichni alloys, which are called feromagnetic. Materials with magnetic powers are used for electrical equipment and for the production of magnets.

Chemistry power characterize the health of metals and alloys to repair the oxidized or to enter into production rіznymi speeches: Kisnem povitrya, razchiny acids, razchiny lakhiv and i n.

To the cheeky authorities, make the following:

corrosion resistance

heat

Corrosion resistance - the quality of metal repairs to chemical repairs before going on the surface of the most aggressive middle ground (corrosion occurs when a user enters a chemical user).

Heat resistance - the health of metals in repairing oxydated at high temperatures

Chemistry of power to fight in the first place for virobes or details that can be used in chemically aggressive environments:

Containers for transportation chemical reagents

pipelines cheery speeches

Attach the tools to the chemical industry

13. Understand: Alloy, component, phase, mechanical sums, solid solutions, chemical spoluks.

Alloy - macroscopic one-sided metal material, which can be stored in a sum of two or a large number chemical elements from the reloading of metal components.

Components are words to set up the system. As a component, there are clean speeches and chemical spheres, as the stench is not disposed in the warehouses in the pre-existing temperature range.

phase - one-sided part the system, which is attached to the other parts of the system and the surface breakdown, when passing through the structure and power rapidly changes.

MECHANIChNA SUMISH (in metalwork) - an alloy of two components, which does not form until it is mutually disassembled in a solid mill and does not enter into cheeky reaction from the apparatuses spoluk. The alloy is stored from crystals of components A and B

Solid solutions are phases of a changing warehouse, in which atoms of different elements are rostered in the foreign crystal solutions.

Chemically connected spoluca is a folding speech line that can be stored from chemically knitted atoms in two or more elements (heteronuclear molecules). Simple words can also be seen as a chemistry, as molecules are composed of atoms, with a covalent link (nitrogen, acid, iodine, bromine, chlorine, fluorine, astatine).

14. Crystallization of metals and alloys

The processes of crystallization of metals and alloys, such as the processes of transition from a hard mill in solid, are connected with the vision of the added heat of crystallization. For this purpose, the process of crystallization of metal or alloy is necessary for the whole hour of cooling (bringing, taking away all the heat).

When you look at the processes of crystallization, you must pay attention to all your mother's fault. rare metal For the alloy, which is warm, and the form, which I accept. The transfer of heat from a rare metal and an alloy of forms does not pass through mitt, as well as the heat conductivity of a rare metal or an alloy and form a final value. Therefore, one-hour crystallization of all metal or alloy from the mold is unfeasible to wind at the same temperatures at all points of its volume.

15. experimentally pobudova diagrams for sub-alloys

16. Rules for phases and responses

In phases it can be a bit of a problem, a solid solution and a chemical one. Otzhe, a single-phase system is a single-phase system, a mechanical sum of two types of crystals is a two-phase system, etc.

By the number of steps of freedom (variance) of the system and the reasonableness of the number of external and internal factors (temperature, pressure and concentration), which can change without changing the number of phases in the system.

The number of stages of freedom of the system, which is in the stage of equalization, and the number of components and phases is accepted as the rule of phases (Gibbs's law). The phase rule for metal systems is to rotate to the level

C = K - F + m,

de C is the number of levels of freedom of the system; Up to the number of components; Ф is the number of phases; t - number zovnishnikh officials(Temperature, vice).

It’s easy to accept, but everything is reconstructed with a constant grip (P = const), the main reception of the offensive viglyad: C = K - F + 1, de 1 is a callous change factor (temperature).

Corroded by the rule of phases, it is clear that there is a change in the number of steps of freedom of a one-component system for the drop of molten pure metal (K = 1; F = 1) Z = 1-1 + 1 = 1, so that the temperature can change without changing the number of phases. Such a system is called monovariant (single-variant). In the process of crystallization, F = 2 (two phases are solid and solid), and K = 1, to C = 1-2 + 1 = 0. This means that two phases are in equal conditions at a strictly singular temperature (melting temperature), won’t be changed, as long as one of the phases is not lost. For a two-component system, which is in a rare mill (K = 2; F = 1), the rule of phases is ma viglyad C = 2-1 + 1 = 2, such a system is called bi-variable (two-variant). In general, there can be a change in two factors of equal value (temperature and concentration), the number of phases does not change. For a whole system with two phases (solid and hard) K = 2, F = 2, according to the phase rule C = 2-2 + 1 = 1, so that due to the low temperature, the concentration is strictly due.

Zastosuvannya rules of phases for diagrams will become the first type (div. Fig.). If you use a solid diagram, it is possible to create a phase mill of alloys in any warehouse at any temperature. So, for example, in the region 1 there is one phase - a rare conflict. The rule of phases is written in the viewer C = K - F + 1 = 2 1 + 1 = 2, i.e. the system has two steps of freedom. For the second regions 2, 3, 4 and 5, the system is characterized by one level of freedom (C = 2 - 2 + 1 = 1).

17. Diagram will be alloyed with mechanical sum

22. Structural warehouses of hard coal alloys

ferite- a whole lot of hard razchin in coal in α-zalizі. The maximum concentration in carbon is only 0.025% (point P). at room temperature- not visce 0.006%. Ferite is soft and plastic.

austenite- hard razchin in coal in γ-zalozі. The maximum concentration in carbon is 2.14% (point E). Austenite is not very hard, plastic, but does not magnetize.

cementite- Chemically based on solid carbon (carbide salt, Fe3C). Concentration in coal, by and large, post-production - 6.67% in coal. Cementite is even hard, crumbly, non-plastic.

It is necessary to see the very type of 2 structural warehouses of hard coal alloys:

perlite(Evtektoid) - mechanical sum of 2 phases - plates / grains of ferite and cementite. Perlite is established as a result of perlite transformation of austenite ("vilny" or to enter the warehouse of ledeburite) with a concentration of 0.8% in carbon when passing the lower PSK line:

A0.8 → Ф0.025 + C6.67

A0.8 → Ф0.025 + C6.67

At the same time, it is possible to pass from the γ-form to the α-form. Mechanical power lies strongly in the size (dispersity) of particles, which are stored in the Danish pearlite.

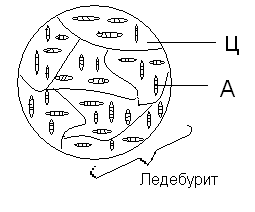

Ledeburite (eutectic)- mechanical sum of 2 phases - plates / grains of austenite and cementite. Ledeburite is established in the hard phase with a concentration of 4.3% in carbon when the lower ECF line is passed:

W4.3 → A2.14 + C6.67

W4.3 → A2.14 + C6.67

Ledeburite structure. C - cementite, A - austenite.

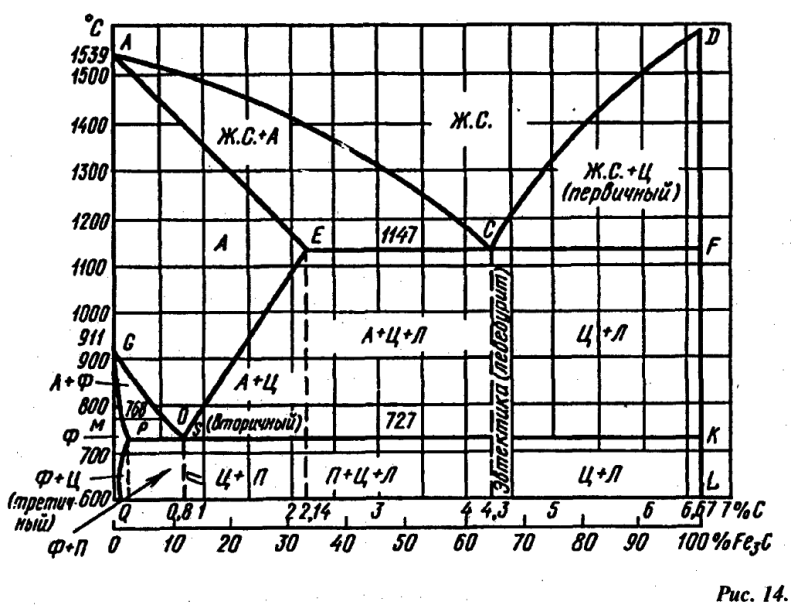

23. Diagram for the alloy of zalizo-cementite

Diagram zalizo-vuglets (zalizo-cementite)- the whole graphical representation of the structure of the alloys, which is stored only from the deposit and in the coal, in the deposits of the general average concentration in the coal and the flowing temperature of the alloy. Diagram zalizo-coal allows visual processes that occur during heat treatment of steel.

Diagram zalizo-vuglets (zalizo-cementite)- the whole graphical representation of the structure of the alloys, which is stored only from the deposit and in the coal, in the deposits of the general average concentration in the coal and the flowing temperature of the alloy. Diagram zalizo-coal allows visual processes that occur during heat treatment of steel.

Diagram zalizo-vuglets (zalizo-cementite). Asked for

line ACD. Linea liquidus. When the alloys are cooled down, the crystallization should not be repaired;

line AECF. Line solidus. When the alloys are cooled down, the entire alloy passes into a hard mill;

line ECF. One is called a line of ledeburite re-making. When the alloys are cold, 2.14% is lower than usual in coal, the phase transforms into ledeburite;

line PSK. The line of perlite re-enactment. When the alloys are cooled down, austenite transforms into pearlite.

Significantly, there are some important points on the diagram:

point E. The point of maximum saturation of austenite in coal - 2.14%, at temperatures 1147 ° C;

point P. The point of maximum saturation of ferite in coal is 0.025%, at temperatures 727 ° С;

point S. The point "0.8% С-727 ° С" is the conversion of austenite with a concentration of 0.8% in carbon into perlite (eutectoid) of the same concentration;

point C. Point "2.14% С-1147 ° С" is the transformation of the line with a concentration of 2.14% in carbon in ledeburite (eutectic) of the same average concentration.

Salted ores are divided into chotiri main types:

1. Magnetite ores (to replace gold at the sight of magnetic oxide Fe304).

2. Geiate ore (Pe20s) -

3. Buri zaliznyaks (zalizo in the form of hydrous oxides of the rose stage of hydration: t ■ Fe2C> 3 LH20) ■

4. Spar wines, which should take place at the viglyadi in carbon dioxide - FeC03.

The main classification is assigned, it is taken in the hospital and metallurgical practice, allowing one to judge about the special features of ores that govern the skin type. Determination of physical power of ores zoom in and out different ways preparation before melting.

Magnetite in Persh Ore. The head nose of saline in cich ores is mineral magnetite-Fe304, which is magnesium oxide - oxide Fe203 FeO. Magnetite reveals 72.4% gold and 27.6% sour. Pitoma vaga magnetite 4.9-6.2.

A characteristic feature of magnetite ores is the appearance of strongly rotated magnetic powers, which are victorious for replacing them in an electromagnet way.

Before the inflow of oxidizing processes, which is introduced in nature, the magnetic zaliznyak is often oxidized to a higher form of zalizny oxide with the last transition from Fe304 to Fe203. As a result, there is a transition to the magnetic bed, which replaces both Fe304, and Fe203, rather than the crystalline form of magnetite. I will call this phenomenon "pseudomorphism". The pseudomorphosis of oxide zaliza over magnetite is called martite. False ore, which is oxidized from March, grows with martite and poly - l u m and r t and t.

Semi-martitami are called ores, in which the variability of the zagalny zaliza is 3.5-7; in martite the price is more than 7. Magnetite ores are more often, less of the types of ores, they are hardened with sirkoy, and some with zinc.

Magnetic zaliznyaks are characterized by a cracked, crystalline structure, which accelerates the renewal of gases during blast furnaces.

The empty rock of magnetic iron ore is stored from the minerals of the primary projection: feldspar, hornblende, quartz and in., T. E. Mineral, which were established in the period of solidification of melted girskogo breed, I will turn on the magmatic campaign of the genera of the magnetic zaliznyak.

Hematite ore. The mineralized minerals in the whole group of ores are anhydrous oxide Fe203-hematite, which should take 70% of the gold and 30% ore. Pitoma wag 5.19-5.28.

The physical nature of hematite ores is even more profitable: from solid crystalline to weak powdery values. Vmіst zalіza in the ores of different genera rises in wide fringes. A lot of piles of cinnamon iron ores are rostered in the middle of crystalline shales and gneiss. In addition, the bulk of the empty rock is stored with silica (Si02) and small amounts of AI2O3, CaO, MgO. Fallow from the geological minds of the establishment of the ancestors of the chervony zaliznyak empty quartz rock, or permeate ore minerals, or perecharovuyutsya with them. The nature of the empty rock is more significant when using the method of bagging the empty ores. Hematite ores, in small quantities, from other large-scale ores, replace the smaller number of small-sized houses (gray, phosphorus, mish'yak).

Foundations of great porosity, the recoverability of hematite ores is more of the recoverability of magnetite.

Buri zaliznyaki. Zaliznymi minerals of a group of buric iron ores є water oxides of iron ore

mFe20:! lH20.

Yak can be seen from the formula, the steps of hydrate oxidation, i.e. There are five types of burial iron ore, which can be developed with the help of liquid water: 1) turit-2Fe203-H20 (5.32o / 0 liquid water); 2) goethite - Fe203-H20 (10.11% water); 3) limonite - 2Fe203-3H20 (14.39% water); 4) Xanthos - derit - Fe203-2H20 (18.37o / o water); 5) limonite Fe203-3H20 (25.23% water).

Most of the iron ore burials of the siege campaign. This is an empty rock to that is a mineral, which was a mineral, which was a mineral from a rose (a mineral salt of a mineral, phosphoric, sulfuric acid), for the sake of a rocky period (clay, bauxite). Mind the prying burrows of iron ore to explain the greater number of steps of the obstruction with small houses - phosphorus, gray and mish'yak.

Along with the cym, there is a viciously clean lineage of brown iron ore, such as Bakalskoe in the Pivdenny Ural.

Storms of zaliznyaks may grow earthen fluff, the shining iron ore will grow more and more. Buri zaliznyaki of some of the greatest light genera may have a powdery oolite structure, for example, such iron ore cannot be found in water without prior lumping.

There is a lot of high porosity of brown iron ore, which grows in the world of ore heating as a result of increased water, the recoverability of its food, less magnetic and worm iron ore

Sіderіti and spar iron. A typical saline mineral of the whole group is siderite FeCC> 3, which takes 43.8% of saline. Pitoma of the vaga sіderita 3.7-3.9.

In the ancestors of the sederita, the part of the zaliza in the carbonic acid salt can be substituted with the other metals from the solutions of the sublayer salts (Ca-Fe) C03; (Mg-Fe) C03 і ін. Wear it all the time zagalna name spar and ironstone. Siderites on the day of the weather and water and it is easy to go into the stormy zaliznyak, so that you curl the surface of the pads of the siderite.

The ancestors of the siedet of the siege campaign (from water races without access to the fortress). Some of the broadenings of the widening differences in siderites replace the amount of mechanically mixed clay, which is called clay siderites. The interchangeable-thickening of the round purchase of pure sidder is called spherosidemitam. The stench is often permeated in the clay, to take revenge on the coal, as organic speeches as a result of geological processes.

Spatovy zaliznyak is characterized by great purity instead of shkidlivy houses.

Bidni spatovy zaliznyak is possible with the success of the electromagnetically charged method with the advancement of ore for the completion of the magnetic authorities. On the basis of some of the other types of ores, the spatovy zaliznyak can be burned without vitrate to the gas for renewal of ore, so as in the process of laying out the countermeasures against the reaction

3FeC03 = Fe304 + 2CO2 + CO - 63470 cal,

as a result, magnesium oxide-nitrous oxide is established, and in addition, oxide is seen in carbon. Remaining can be found in the ore oxide to magnetic oxide-oxide (Fe203 Fe0) according to the reaction

3Fe2C), + CO = 2Pe304 + CO2.

With the territorial closeness of the genera of oxidized ores and spar iron ores, sparry iron ore allows the supply of magnetic power about different types of ores, and thus the possibility of electromagnetics is prevented by themselves.

The main indicator of the quality of gold ore є instead of niy zaliza - chim vono vishche, tim for іnshi pryvnykh

ore is more beautiful, - and navpaki. However, in addition to the growth, the factories also increase or decrease the value, they are referred to: a mineralogical warehouse, a physical mill, instead of a school of livable houses, the quality of life

So, for example, when there is a deposit in ores near the viglyadi BeCO3 and / zFe20s-mH20 in carbon dioxide and hydrated vologa, it is seen in the blast furnace at altogether low temperatures, it is practically impossible for the coke to consume the heat of the gases without vitrati. If it’s seen, instead of going into a solid surplus, it will move, grow, as well as the recoverability of a surplus. As a result, the spar and burrow iron ore castings for the chavun will be cheaper, less for the worms and magnets with the same amount of gold, and with the same variability, the chavun can be stagnant.

To a similar result, bring the presence of basic (CaO, MgO) and acidic (Si02, A120s) oxides in empty rocks. We reduce the amount of time spent with cimi oxides, so that in case of blast furnace melting can be carried out without adding vapnyaku (self-melting charge). Tse lowering the slag and quickly vitrati for the whiplash7 chavun; blast-furnace smelting can be carried out on ores with a decrease in bulk. The same result can be corrected with the presence of ores with a basic and sour empty rock, melting it spirally without adding vapnyak.

The physical mill of ore and the specificity of the ore is injected into the preparation of ore (crushing, grading, agglomeration and aggregation) and transportation.

I will look at all the vyshevikladeni factories, the most beautiful vortex on the basis of the pre-blast furnace smelting; It is possible to create a visnovok about the victorian zaliznoy ore of the skin genus, either without zbagachennya, or else zbagachennya according to the most rational scheme for the given ore.

Bagaty ores are called those, which are used for storage in the domain name floating without storage, and are called as single ores, which are used for storage in the domain.

It’s a part of the reserve to deposit because it’s easy to get into the power of ore grain from an empty breed and because of the difference in physical power of the rock and ore minerals, to see the remainder in the concentrate.

Obviously, with larger grains represented by ore minerals, it is easier to reach them from empty rocks.

With small sizes of ore minerals, there is a need for mineral and fine refined ore before waste ore. Part of the agglomerate from concentrates of single ores, which will require fine refinement before the preparation, if it is more important for the agglomerate from concentrates of greater refinement.

Magnetite ores are good and very cheap to be stored using the electro-magnetic method; for hematite ores, gravitational methods are often used, based on the growth of the breeding rocks and ore mineral. We will stay for an hour to work on the preparation of the flotation method for the recovery of hematite ores and quartzites.

Burial zaliznyaks can be fired in a magnetic way, with a kind of magnetic power, zalous minerals can be used as a route of the most common ore at temperatures of 550-600 ° С.

In bessemerivskyi Kryvoryzky ores, instead of phosphorus, it is not more than 0.022%.

Rudy for the high-temperature heating of the pre-Martin chavun represents the most popular category. We'll wash my mind in all the cases, as small as possible, instead of the sisters, which are tied up from the covered vitrates of firewood and fluxes. There is also no need for a house for chrome, which, during blast furnace melting, turns into chavun, and during open-hearth melting, it oxidizes and turns into slag in the case of viglyad, oxide, remains viscous and thick, which greatly slows down open-hearth melting. For ore with 60% Fe and more, instead of chromium, up to 0.4о / о can be tolerated.

Great value for assessing the quality of ores may be of physical power. Naygolovnіshі from them - lumpiness and volition

Blast furnaces, when powdered, ore is enclosed in them, cannot be efficiently processed. Proceeding between shmats and clogging empty ones, creating a great support for the flow of single-blowing gases, the need to improve the grip of blowing. It is clear that there is a great number of industrial problems, it will be necessary to break down the correct gas distribution over the stove, so that the stove runs to the point of breakdown. An important part of other and fine ore fractions is to be vinified from the oven near the saw, so it can also bring the saw to breakdown, and sometimes it’s going to break the oven, not even thinking about wasting ore and vitrates on the purified gases, tidying up and reworking the saw.

Allowances in the ores of other and fine fractions reduce the rate of ores.

It is permissible in the ore of other fractions to be deposited in the form of furnaces, in which smelting is carried out, in the grip of dutty, in the form of production of great shmatkiv and others, i.e. in the form of granulometric characteristics of the ore. Non-essential, from the point of view of wine from the oven, є fraction of ore with grain sizes of 2 mm and lower.

A great range of coarseness between the maximum and minimum sizes of ore grains is also negligible, which is why the gas permeability of a stack of melting materials and overshooting of the robotic blast furnaces is increased. Bazhano, ore was strictly classified in terms of size, for example 80-50 or 50-25 mm. In order to ensure the safety of the mind, it is necessary to establish fractional sorting and agglomeration factories.

Great influx into the minds of the exploitation of ore genera and the processing of ores, given the moisture capacity of the ore. Hydroscopic, vologo-ore ores are important to transport when they stick to the walls of wagons, bunkers, lines and flows.

When there is a drip, open a grid of screens to fill up and drop the ore in coarseness.

The crushing of such ores can also become difficult as a result of sticking of the working parts of the crushing apparatus.

Clay is an empty rock, sutnya zzvychay drill Zheleznyak, because of the plastic power. Loss of moisture is interconnected with moisture capacity and, at maximum moisture content, pass through the bunkers, zeniters and funnels. The strength of the ore ore when making ore for skin ore vologosti up to mint cracking when the breasts are larger or smaller in size are severely difficult when the ore is rattling, when the ore is rattling. Conducted by the Institute "Mekhanobr" the prospecting of Kryvory ores, which reveals a large number of fine fractions, has shown that it is possible to find a lot of crystalline ores, such as heme - Titov ores of Kryvorizhya, easy breasts. The pre-session of the most important mines in Krivorizhzhia showed:

1) ore content up to 4% for screening efficiency;

Riy ore on the bed is intensively crumpled, so that the process of classification on gurcot is practically crumpled.

The fight against plasticity and transportability of moisture-consuming ores is one of the most important enterprises. As soon as in the guided application, the prospecting of Kryvyi ore is difficult to determine within a wide range of vologos, and by the day it expands only for the process of enrichment, then in the case of buried iron ore, the plasticity of ore is able to accelerate in a wide range of conditions. Piece drying of such ores lays down only those operations, which follow the dry, difficult ones, tied with the transport of the syroe ore in the drying room and into the drying unit, will be overpowered.

In order to fight for the plasticity and transportability of iron ore borers є the removal of empty clay rocks from them, which is one of the broader ways of sacking iron ore borers.

The range of ores that can be stagnated for the high-melting of open-hearth chavun and that are called open-hearth ores, is the category of ores, which I will name, but it is stagnant when the chavun is transferred to steel in the open-hearth and electric ovens. Open-hearth ores are produced in a high volume-62-65o / 0 and in great folds. With the development of the steel-making industry and the one-hour change in the reserves of lumpy lump ores in some metallurgical regions, there have been serious difficulties in securing factories with abundant open-hearth ore. Vinikla is necessary to replace lumpy ores with lumpy concentrates.

The main vimoga is a high vm_st zaliza, - it is to be presented to the ore for the open-hearth vyrobnitstva, it is obviously easy to reach the shlyakh zbagachennya. Naivazhche prepare lumpy material to keep up with your physical powers and lumpy ore from concentrates of zagachennya.

It will remain an hour for the open-hearth technology to successfully shut down the agglomerate; Pitoma of the agglomerate is guilty of buty 3.2-3.3 g / cm3.

If it was forgiven to say "zalizny", may be in uvaz - motsny, mitsny, non-lucid. Too it is not wonderful to feel: "good will", good health "and navi" bad fist ". Well, also good?

Name history

Zalizo in a pure viglyad - metal of a silky color, in Latin it is called Fe (ferum). About the rossiyskoy name vcheni talk. One vvazhayut, as soon as the words "dzhaldzha" are called, which in Sanskrit means metal, іnshi singing, as well as the word "Zhel", which means "blischati".

How did the people otrimal zalizo?

Farther zalizo opinilis in the hands of the people, falling from the sky. Also, the meteorite boules may be more abundant. They depicted objects of metal in blue - the color of the sky. Bagato people may think of the heavenly prowess of the zealous signs - the gods gave them nothing.

So also "zalіzniy vіk"?

If Lyudin smashed the bronze, she felt the "bronze wick". Piznish yomu for a change come "zalizny". This is the name of the hour, if the khalibi, the people who are alive on the birch of the Black Sea, smelting in special furnaces of special sorts began. Otrimaniy metal bouv of a beautiful silver color and not rzhaviv.

Do you want gold virobi to buy food?

In those hours, if it was melted from meteorites, it was mostly embellishments that could be worn, it could only be worn by people of a noble family. Often, they embellish the frame with gold, and in Ancient Rome navit hoops boules zal_znym. A leaf was saved, written by one of the pharaohs of Egypt to the king of the Hittites, de that asking for the money, pay in gold in any amount.

Holy miracles, broken from zaliza

In India, in Delia, there is an ancient column of the head of more than seven meters. Wonderful from the clean room in 415 rots of our country. Ale і at once for nіy dumb ni follow irzhi. Behind the legend, a dot to the colony with his back is a vikonannya of the famous bazhannya. Another great value for sporud is the Eiffel Vezha. For the preparation of the symbol of Paris, more than seven thousand tons of metal were needed.

Are the stars taken zalizo?

Schob trim the zalizo, zalizna ore is required. Tse of minerals, stone, in which gold is tied with small words. Cleans up the dust from the houses, and removes the required metal. For example, syruvino can be magnetic zaliznyak, in which up to 70% zaliznyak can be found. Zheleznyak - black or dark gray stone. In Russia, I add it to the Urals, for example, in the nadra burn, as it is called - Magnitna.

Yak shoot ore?

The genera of gold ore are not only in Russia, but also in Ukraine, in Sweden, in Norway, in Brazil, in the USA and other countries. The stocks of a wikipedia do not skip the same, they can only be repaired in the same way, if they seem to be great, even rozrobot kostuє expensive and it will not pay off, if it’s not enough.

Most often zaliznu ore vidokuvayut in an open way. Dig a majestic hole, yak to be called kar'єr. Vona douzhe gliboka - pivkilometer in glybin. And the width of the deposit lies in the one near the ore. Special machinery picks up ore from an unused breed. Then we can bring vantages to the backwaters.

However, do not be-yak ancestry can be broken up in this way. Yaksho ore gliboko For the mine, there is a small well, which is called a stovbur, and at the bottom of the corridor there is an entrance - drifts. The mines are going down. All people are important, it stinks to know the ore and pick up, and then transport it to the surface in shms. The robot of the mines is not safe, even the mine can collapse, and still below the safe gasses, that before the hour, people can suffer, if they want the stench of safeguarding and see the rules of safety technology.

Yak z ore go zalizo?

If you just get some ore, it's not all! Adzhe otrimannya zaliza from ore is a difficult process. Wanting to viplava zalizo from the ore have long been imposed. For a long time ago, they were busy with the forging, the stench was blowing by the people. At the special pich, yak called the forge, they put the ore and the village in the village, and then pidpaluvali. However, the temperature of the furnace is insufficient for the whiplash, so the fire was blown out, the vikoristovuchi mikhi - pristosuvannya, you see it with great power. A handful of them collapsed with their hands, and suddenly they were forced to vikoristovuvati the power of the water. As a result of the heating of the vikhodil, the masa was baked, yaku, the forging of the kuvav, I will need a shape for the flesh.

alloy

Most often the vikorystovuvatsya (that and at the same time vykorystovuyutsya) not purely zalizo, but steel abo chavun. Tse alloy zaliza z carbonized with gas... If in alloys more than 2% in coal, then go chavun. It’s German, but it’s easy to melt and you can give it a shape. If the carbon is less than 2%, then. Vona duzhe mitsna and vikoristovuyutsya for the preparation of helpless corny speeches, cars, zbroi.

Infectious, zychay, zastosovytsya іnshі methods, I want the principle їх the same: float with added carbon dioxide at high temperatures. In this hour for the tsієї meti vikoristovuyut the electrician.

How can a human body want it?

Yakshho people are not vystachak zaliza, vin hvorin. tsey metal is required to confirm hemoglobin, yaky delivering kisin skin clitintsi tila. That requires products, a lot of zalizom - a liver, beans, an apple.

I’m glad to see you, I’m glad to bachiti you